The Line Grinder software converts the Gerber plots of PCB circuits into GCode which can then be used to create isolation milled circuit boards. The Eagle software (freeware for smaller PCB boards) is one product which can be used to create the PCB designs suitable for isolation milling. There are a number of things you need to know in order to configure Eagle so that it will save Gerber plot files in a format which the Line Grinder can read.

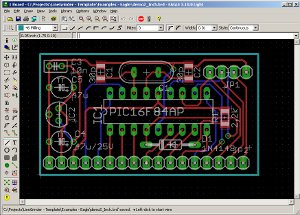

The following is a step-by-step tutorial using the demo2_inch.brd Eagle PCB design sample which is installed with the Line Grinder software in the Examples - Eagle sub folder. Click on any of the images to make them larger.

The image below shows the demo2_inch.brd PCB design sample open in the Eagle software.

One of the hardest problems to solve when creating isolation milled circuits is how to align the top and bottom copper layers. Line Grinder resolves this issue by requiring pads of a specific size called Reference Pin pads to be added to the PCB. You determine the size you use and tell the Line Grinder software (in the Isolation Cut File Managers) what that size is. Often the Reference Pin Pads are co-incident with the mounting holes of the PCB. If you do not want these pads on your board (as in the example below) - no problem. Just put them outside the border.

The following steps will now place the first Reference Pin pad. Since we do not want to have any mounting holes drilled on this board we will place the Reference Pin pads outside the PCB border.

The image below shows the bottom left Reference Pin pad once it has been sized and positioned. Note that it is centered over a grid dot. This will make it easy to place the other Reference Pin Pads an identical distance from the border.

The main thing about the Reference Pin pads is that they must be of a known unique size, they must be in a rectangular formation and they must be the same distance from the board edges. They can be inside or outside the board - but it is critical that they are equidistant from the edges. You must have at least two Reference Pin Pads. If the IsoFlipMode in your Isolation Cut File Manager is Flip_X then the Reference Pin pads must be on the same line parallel to the X axis. Similarly if the IsoFlipMode in your Isolation Cut File Manager is Flip_Y then the Reference Pin pads must be on the same line parallel to the Y axis. In general it is easier to just put four Reference Pin Pads on the PCB - each equidistant from a border corner.

Note the easy way to create the rest of the Reference Pin pads is just to copy the first pad placed in the step above and then paste it into the design where needed. Once dropped in place, you can easily drag the pad about to get the position right.

The image below shows the PCB with four Reference Pin pads placed. Click on the image to enlarge it and note that the pads are equidistant from the border edges and are in a strict rectangular formation.

Now that the Reference Pin pads have been placed on the PCB, it is time to save the design as Gerber and Excellon files. These files are what the Line Grinder software will read in order to produce the Isolation Milling GCode (and other useful GCode as well). Before we do that we have to adjust a few settings in the section of the eagle.def file which controls the codes emitted to the Gerber plot files. If we do not do this Eagle will include lines of code in the Gerber output which the Line Grinder software will not be able to process. The steps below describe the proceedure.

The image below shows the eagle.def file after the adjustments have been made. Note carefully the placement of the semi-colons - the appropriate areas have been highlighted in red.

Now that eagle.def file has been adjusted, it is time to save the design as Gerber and Excellon files. These files are what the Line Grinder software will read in order to produce the Isolation Milling GCode (and other useful GCode as well). Click on the File menu item at the top of the screen and then choose the CAM Processor ... sub item. Set the Device option to GERBER_RS274X. This will invoke the output using the settings adjusted in the eagle.def file in the step above. The Gerber Output Form is seen in the image below.

Eagle does not seem to have a method of automating the output of the Gerber files or saving the configurations. This means that each plot must be saved individually and the appropriate file name specified for it when the output is saved. The discusson below illustrates this process for the traces and pads associated with the Bottom Copper layer.

The image below show the Eagle CAM Proceesor output form just before the bottom copper Gerber code is saved..

As mentioned above, the other plots (top copper, board outline) will need to be output. This can be done using the methodology described in step 6. Appropriate values for these layers are:

At this point, the files are ready to be read by the Line Grinder software. Once the Line Grinder software is started you will need to create some File Managers - and configure them to settings suitable for your purposes. There is a button on the Settings Tab entitled Add Managers for Eagle that can be used to create a useful set of File Managers to get started with. You will need to adjust the settings as appropriate.

Note that the default setting for the Reference Pin pads is 0.125 inch and the above discussion sets the pins to a value of 0.100 inch. Using the default settings, the Line Grinder software will not be able to find the Reference Pins, and will return an error message when the file is opened. Change the ReferencePinPadDiameter setting in the IsolationCut File Managers for the Top and Bottom Copper layers to a value of 0.100 to fix this problem.

The image below shows the demo2 Top.gbr file after conversion to Isolation GCode in the Line Grinder software.